Steampunk Nerf Maverick: Rev 6A

Once I chose the color scheme (with the help of my modest Photoshop skills), I started the task of modifying the real thing. Here we go, step by step.

First, we take it apart. I used masking tape to keep the screws together. After I had more than a few pieces to keep track of, I started labeling them and putting them into ziploc bags.

Everything has been disassembled and lightly sanded.

Everything has been washed and is drying.

The bits and pieces have been labeled and placed into ziploc bags. Note the bag labeled “unknown spring”. Yes, I have already lost track of where something goes. Sigh.

These are the ornamental bits I bought at Michael’s. The curlicue flourishes were something like $5 a pair, while the bag of little oval things was about $5 for a dozen.

And now those are lightly sanded and washed, as well.

The decorative bits are glued on (with cyanoacrylate), things have been washed again, and are drying.

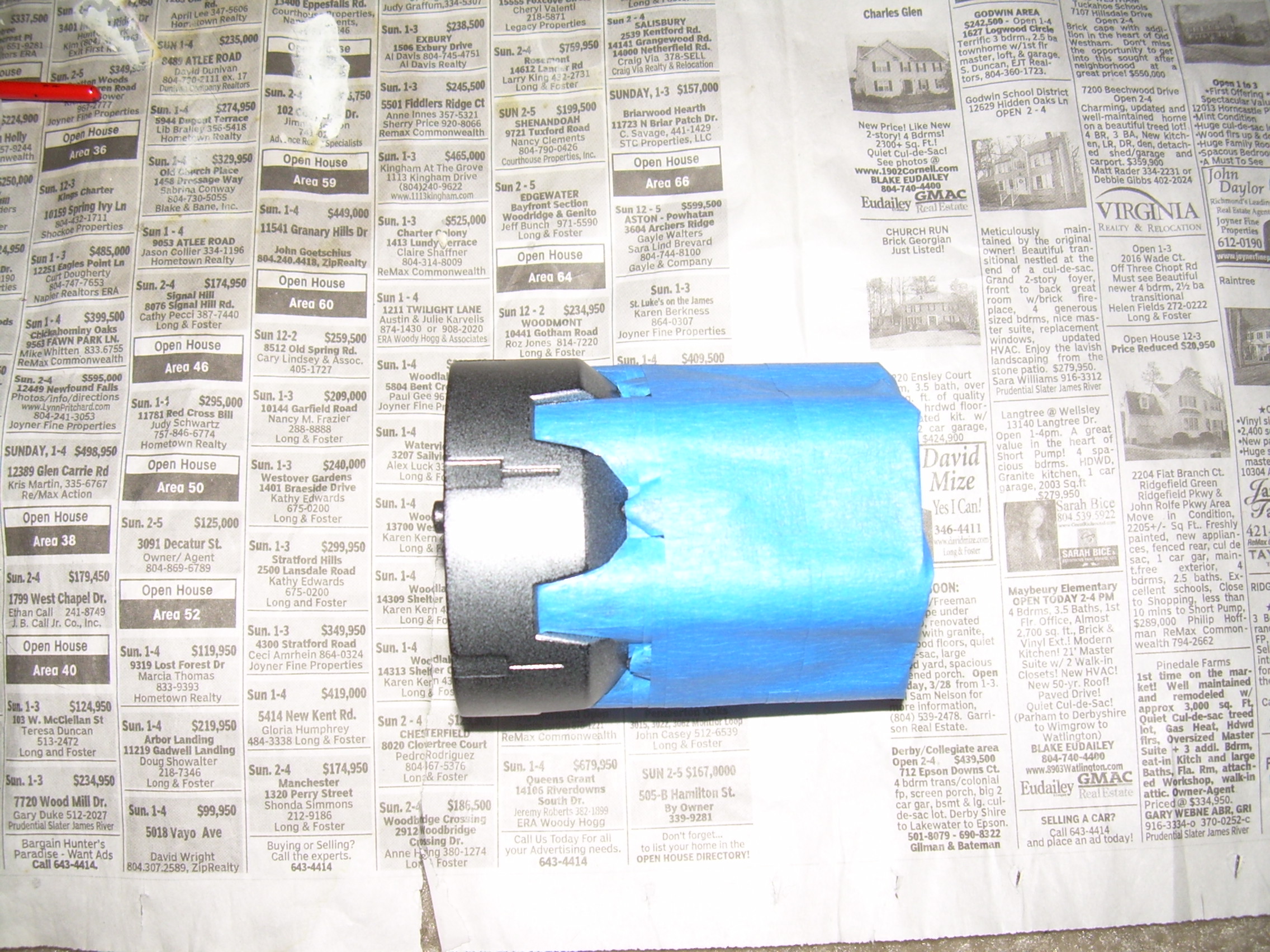

Everything has been given a couple of coats of satin black.

I assembled most of the large parts (without screws), and took a photo to use as the basis of my color tests. There is probably a word for assembling something without using the screws, but I do not know what it is.

I thought the cylinder deserved its own photo.

This is the first coat of “antique brass”. I will go over this lightly with “brass”.

Masking off the cylinder was the single most time-consuming part. There are at least 50 individual pieces of masking tape on this thing.

This should be the last thing I need to mask off: the upper receiver, under the slide.

I painted the upper receiver black, and then gave it a mist of silver. I think that this gives it a nice retro “steel” look.

And naturally, the black paint seeped past the masking tape, and the masking tape stuck to the silver and pulled it off. I tried using some acetone to take the black off, and that did nothing, nothing, nothing… and then went through all of the layers of paint down to the yellow plastic. Son of a…

Okay. So I re-masked and then re-painted it (just in the damaged areas, to the best of my ability), and it looks okay. In retrospect, I should have sanded the edges of the damaged areas, because you can see those edges if you look carefully. But screw it: the whole point of steampunk is that things are hand-made, not mass-produced in a factory, so some minor flaws are acceptable.

Here we are. All the pieces have been painted, and are ready for assembly. You may not be able to tell in this photo, but I used a brush to paint some black in the creases and edges, to give the parts a “used” and slightly dirty look.

As I assembled the pieces, I used a kind of dry teflon-based lubricant on the moving parts. I think that this was a huge improvement over the silicone gel I used to lubricate the prototype.

Assembly has begun! And wouldn’t you know, I still do not know where that mystery spring goes. Not only that, but I have a mystery screw, now, too. I stared at it for a good long while, but eventually I had to give up and go disassemble my unmodified Nerf Maverick for comparison.

I immediately saw where the mystery spring was, but it took a long time for me to spot the mystery screw. It’s inside of the indexing mechanism.

The best thing — well, maybe not the best, but a great thing — is that it works! My prototype fails to fire about 85% of the time. I think that is partly because it has so many layers of paint, and also because I used silicone gel for lubrication. Rev 6A has, at most, half the layers of paint that the prototype has, and I used a dry teflon-based waxed lubricant on the moving parts.

All in all, I am very pleased.

I have one thing left to do, but it will need to wait a while, because work and school are keeping me busy: I want to put black leather on the grip, where it is currently painted black.

![[x]](/images/sigil_md.jpg) Blackmoor Vituperative

Blackmoor Vituperative